30-40KG/H Screw Oil Press for Peanut, Soybean, Sunflower Seeds

- Home

- Product

- Hot Pressing Production Line

- 30-40KG/H Screw Oil Press for …

30-40KG/H Screw Oil Press for Peanut, Soybean, Sunflower Seeds

Power : 2.2Kw

Product capacity : 30-40kg/h

Weight: 220kg

Fit for :Peanut, soybean,sesame, sunflower seeds,coconut, olive,hemp seeds,black seeds and so on.

| Type: | Cold and hot oil press |

| Voltage: | 220V/380V/440V |

| Material: | Carbon steel |

| Weight: | 220kg |

| Degree of automation: | Automation |

| Dimension: | 1 Year |

Compliance with certification – CE, ISO, GMP standards, support export demand.

Olive-Tech is a leading supplier of professional high-end oil presses and fully automatic oil pressing production lines. We are committed to providing efficient, energy-saving and intelligent oil pressing solutions to customers around the world, covering the pressing needs of various oil crops such as peanuts, soybeans, rapeseed, sesame, walnuts, coconuts, etc.

| Screw oil press machine parameters | |||||||

|---|---|---|---|---|---|---|---|

| Model | OT-60 | OT-70 | OT-80 | OT-100 | OT-125 | OT-150 | |

| Screw diameter | 55 mm | 60 mm | 65 mm | 100 mm | 110 mm | 140 mm | |

| Screw speed | 52 r/min | 48 r/min | 47 r/min | 38 r/min | 36 r/min | 35 r/min | |

| Power | 2.2 Kw | 3 Kw | 4 Kw | 7.5 Kw | 15 Kw | 30 Kw | |

| Product capacity | 30-40 kg/h | 50-60 kg/h | 80-100 kg/h | 120-150 kg/h | 200-300 kg/h | 500-600 kg/h | |

| Oversize mm | 220 kg | 280 kg | 350 kg | 700 kg | 1100 kg | 1400 kg | |

| Oversize mm | 1000×780×1100 | 1200×860×1200 | 1300×1000×1300 | 1600×1100×1600 | 2100×1300×1500 | 2300×1500×2700 | |

| The output of the machine refers to the pressing volume. The output varies for different raw materials. The actual output should be taken as the standard | |||||||

Introduction of screw oil press

The oil screw press has the following characteristics

1. Edible Oil Processing Plants

Widely used for pressing sesame, peanuts, soybeans, sunflower seeds, rapeseeds, and other oilseeds. Ideal for medium and large-scale oil production lines.

2. Agricultural Cooperatives & Farms

Helps farmers process self-produced oil crops, increase product value, and achieve efficient long-term oil production.

3. Grain & Oil Shops / On-site Oil Workshops

Supports on-site pressing with transparent processing, offering customers fresh and high-quality edible oil.

4. Food Processing Industries

Provides high-quality raw vegetable oil for food manufacturers, ensuring stable supply for product production.

5. Supermarkets & Commercial Kitchens

Can be used for fresh oil demonstration or on-site pressing to enhance brand image and customer trust.

6. Suitable for Various Oil seeds

Compatible with Almond / Avocado / Basil / Coconut / Corn Germ / Cotton Seed / Flax Seed / Groundnut / Mustard / Olive / Palm / Peanut / Pinenut / Pumpkin Seed / Rap Seed / Rapeseed / Safflower Seed / Sesame / Soybean / Sunflower Seed / Tea Seed / Virgin coconut / Walnut / Wheat Germ and many other oil-bearing crops

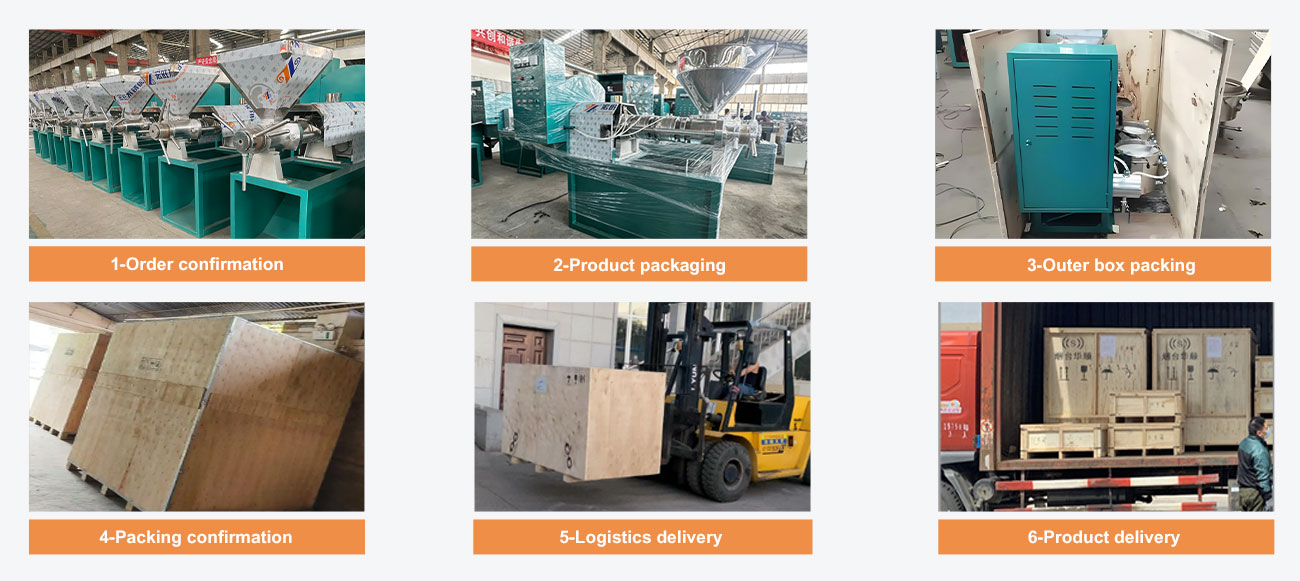

1. Order confirmation

After the customer places an order, we immediately confirm the product information, quantity, accessories and packaging requirements to ensure that all details are accurate and error-free.

2. Product packaging

Preliminary protective packaging should be carried out according to the product type, such as bubble wrap, shockproof film, anti-scratch protective layer, etc., to ensure that the product is not damaged during transportation.

3. Outer box packaging

Pack individual or multiple products into special thickened wooden crates as required, fill the interiors with cushioning materials, seal the outer crates and affix transportation labels.

4. Packaging confirmation

Quality inspection personnel check the packaged products, inspecting the quantity of products, the firmness of the outer boxes, and whether the labels are correct.

5. Logistics delivery

According to the transportation mode selected by the customer (sea/air/express), arrange for the logistics to be dispatched from the warehouse and provide the tracking number for real-time viewing of the transportation progress.

6. Product delivery

The products are safely delivered to the customers. If there are any issues with the delivery, we will provide full after-sales support to ensure customer satisfaction.

GET IN TOUCH

Email us with any questions or inquiries or use our contact data. We would be happy to answer your questions.

Olive provides complete oil press and refining solutions for all production needs.